Latest Trends in Manufacturing Management

- fruiSCE

- /

- May 21, 2024

- /

- Views

In the dynamic landscape of manufacturing management, staying abreast of emerging trends and technologies is paramount to driving innovation, efficiency, and competitiveness. As we navigate through 2024, the manufacturing sector continues to undergo profound transformations driven by digitalization, automation, and the adoption of advanced technologies. From Industry 4.0 initiatives to the integration of Artificial Intelligence (AI) and robotics, manufacturers are embracing new paradigms to optimize processes, enhance productivity, and meet evolving market demands. This blog explores the key trends shaping manufacturing management in 2024 and offers insights into how organizations can leverage these trends to propel their operations forward in the digital age.

Digitilization and Industry 4.0:

Digitalization and Industry 4.0 represent significant shifts in the manufacturing landscape. Industry 4.0, often termed the fourth industrial revolution, marks a transformative phase propelled by cutting-edge technologies like the Internet of Things (IoT), artificial intelligence (AI), and cloud computing. This paradigm integrates advanced digital technologies into traditional manufacturing processes, enabling real-time data collection, analysis, and informed decision-making. By embracing Industry 4.0 principles, manufacturers can optimize operational efficiency, enhance product quality, and swiftly adapt to changing market demands.

Workforce:

Advancements in technology present opportunities for workforce development in manufacturing. Employees formerly engaged in repetitive tasks are now transitioning to roles demanding problem-solving skills. Manufacturing engineers, pivotal in production optimization, are in high demand, tasked with conducting cost-benefit analyses and troubleshooting production issues. Similarly, digital twin engineers, managing communication between physical and digital realms, play a critical role in streamlining manufacturing operations. As the industry evolves, workforce upskilling and reskilling become imperative to meet the demands of a digitally-driven manufacturing landscape.

Sustainable Manufacturing:

Sustainability is emerging as a core consideration in modern manufacturing practices. With conventional manufacturing processes often exerting a significant environmental impact, sustainable manufacturing initiatives aim to mitigate these effects. Embracing renewable energy sources, implementing eco-friendly production processes, and adopting circular economy principles are key strategies. By minimizing waste, conserving resources, and reducing harmful emissions, manufacturers align with evolving consumer preferences and regulatory requirements, fostering environmental stewardship and long-term business sustainability.

Additive Manufacturing:

Additive manufacturing, also known as 3D printing, revolutionizes traditional manufacturing processes by enabling rapid, cost-effective production of intricate designs. Leveraging computer-aided design (CAD) technology, additive manufacturing facilitates the creation of complex structures impossible with conventional methods. This versatile technology finds application across diverse industries, including aerospace, healthcare, and automotive sectors. While challenges remain in supporting mass production, ongoing innovations in additive manufacturing promise enhanced scalability and affordability, unlocking opportunities for mass customization and localized production.

Smart Manufacturing:

Smart manufacturing harnesses the power of machine learning and analytics to optimize productivity and efficiency in manufacturing operations. By making real-time data accessible and actionable, smart manufacturing empowers informed decision-making and drives operational excellence. Integrated with Industrial Internet of Things (IIoT) devices, smart manufacturing systems monitor equipment performance, anticipate maintenance needs, and streamline production processes. As the manufacturing landscape evolves, smart manufacturing solutions continue to revolutionize industry practices, offering transformative benefits in terms of productivity, quality, and agility.

Digital Twins:

Digital twins represent a paradigm shift in manufacturing, offering virtual replicas of physical systems for real-time performance monitoring and optimization. These digital counterparts, fueled by sensor data and analytics, enable continuous assessment and adjustment of production assets. In product development, digital twins expedite testing and refinement processes, minimizing time and resource investments. Extending to factory environments, comprehensive digital twin models simulate scenarios to drive efficiency and safety enhancements. Heading into 2024, digital twins are poised to play a pivotal role in shaping the future of manufacturing, facilitating efficient, adaptable, and sustainable operations.

Predictive Maintenance:

Predictive maintenance, a cornerstone of modern manufacturing, is evolving to embrace predictive resolution. Rather than merely identifying equipment anomalies, predictive resolution offers insights on how to address issues effectively. By leveraging AI, machine learning, and natural language processing (NLP), manufacturers can extract actionable insights from vast datasets, enabling proactive maintenance and minimizing downtime. As predictive resolution technology advances, it becomes more accessible, empowering manufacturers to optimize equipment efficiency, reduce costs, and enhance operational resilience.

Artificial Intelligence and Machine Learning:

Artificial intelligence (AI) and machine learning (ML) technologies are revolutionizing manufacturing, driving improvements in productivity, quality, and operational efficiency. AI enables real-time data analysis, allowing manufacturers to gain insights into production processes and identify anomalies or defects. Machine learning algorithms further refine decision-making by recognizing patterns in data and facilitating predictive maintenance. As AI and ML applications continue to expand, manufacturers benefit from enhanced decision-making capabilities, improved operational performance, and streamlined supply chain management. In 2024, AI and ML are poised to play a central role in shaping the future of manufacturing, driving innovation and competitiveness across diverse industries.

Big Data and Analytics:

Big Data and Analytics are driving significant advancements in manufacturing, offering insights that enable data-driven decision-making and process optimization. By collecting and analyzing data from various sources, manufacturers gain a comprehensive understanding of their operations, supply chains, and customer preferences. Advanced analytics tools facilitate predictive modeling, demand forecasting, and quality control, empowering manufacturers to improve efficiency, reduce costs, and enhance customer satisfaction. In 2024, the focus will be on extracting meaningful insights from Big Data to drive innovation, improve productivity, and fuel business growth.

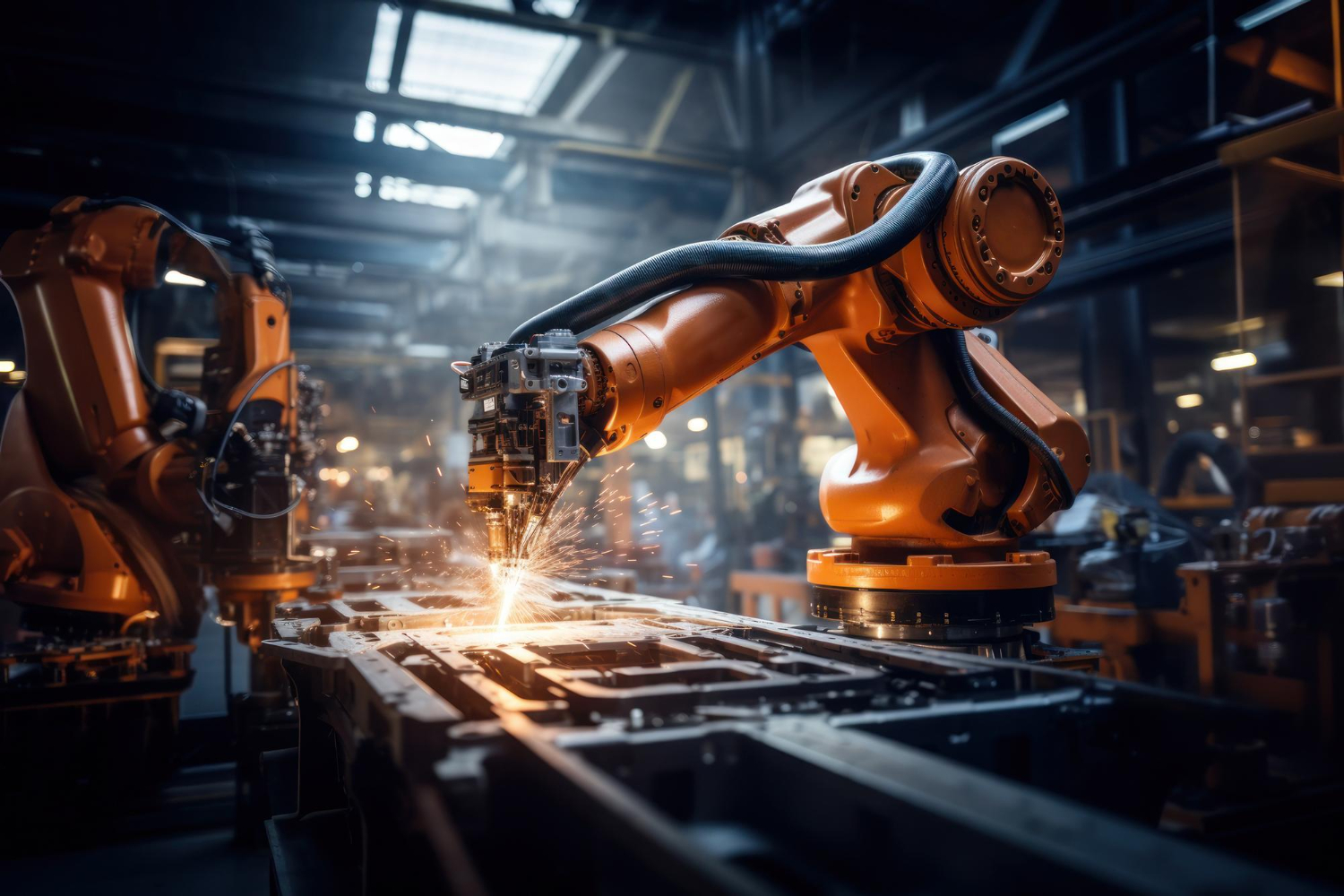

Robotics and Automation:

Robotics and automation continue to revolutionize manufacturing operations, enabling greater efficiency, accuracy, and flexibility. Robotic process automation (RPA) automates repetitive tasks, while collaborative robots (cobots) work alongside human workers to enhance productivity and safety. Integration with IoT sensors and AI algorithms enables smart manufacturing, where robots can adapt to changing production requirements in real-time. Robotics and automation technologies empower manufacturers to optimize workflows, reduce lead times, and meet customer demands with agility and precision. As the adoption of robotics and automation accelerates, manufacturers can expect to achieve new levels of efficiency and competitiveness in 2024 and beyond.

Augmented Reality:

Augmented Reality (AR) offers immersive experiences that enhance manufacturing operations and training processes. By overlaying digital information onto the physical environment, AR enables technicians to visualize equipment components, access real-time data, and receive step-by-step instructions for complex tasks. AR applications streamline maintenance, repair, and assembly processes, reducing errors and improving efficiency. As manufacturers embrace AR technology, they can enhance employee training programs, optimize production workflows, and accelerate innovation. In 2024, AR is poised to become a mainstream tool for enhancing manufacturing productivity and driving continuous improvement initiatives.

As we conclude our exploration of the trends in manufacturing management for 2024, it's evident that the industry is undergoing a period of rapid evolution and innovation. From digitalization and Industry 4.0 to robotics, AI, and augmented reality, manufacturers are leveraging cutting-edge technologies to drive efficiency, agility, and sustainability across their operations. By embracing these trends and harnessing the power of data-driven insights, organizations can position themselves for success in an increasingly competitive global market. As we look ahead, it's clear that the future of manufacturing management lies in embracing innovation, embracing change, and continuously adapting to meet the demands of tomorrow's manufacturing landscape.