fruiSCE®

Achieve Supply Chain Excellence with fruiSCE - Your All-in-One Solution

fruiSCE®

Supercharge your Supply Chain with AI, ML, IIoT, and Process Mining for unrivaled competitiveness.

fruiSCE®

Connect, Collaborate, and Conquer with fruiSCE's Supply Chain Business Network

fruiSCE®

Embrace the Power of Industry 4.0 with fruiSCE - Your Comprehensive Supply Chain Solution Stack

Supply Chain Digital Transformation

Welcome to the ultimate destination for complete solutions in Supply Chain Digital Transformation powered by our innovative product suite, fruiSCE. We understand the challenges that businesses face in managing their supply chains amidst the complexities of global sourcing, market fluctuations, and ever-changing customer demands. That's why we have developed fruiSCE as the fruition of supply chain excellence.

At fruiSCE, we recognize the crucial role played by planning, manufacturing, transportation, warehousing, global trade, order fulfilment, procurement, quality, and finance in achieving supply chain excellence. We know that it's no longer just a goal but a necessity for organizations to excel in these areas. With fruiSCE, we empower businesses to transform their supply chains into interconnected ecosystems through cutting-edge technologies and digitization.

fruiSCE leverages the power of supply chain business networks, creating collaborative platforms that facilitate seamless communication and integration among stakeholders. By connecting suppliers, manufacturers, distributors, and customers, fruiSCE establishes a cohesive network that ensures real-time visibility, efficient coordination, and streamlined operations. This interconnectedness enables optimized decision-making, enhanced responsiveness, and agile adaptation to market changes.

Supply Chain Excellence powered by Cutting Edge Technologies

fruiSCE harnesses the potential of AI-driven models, utilizing advanced analytics, predictive insights, and intelligent automation. Through these models, businesses can extract actionable intelligence from vast amounts of supply chain data, making informed decisions, anticipating future trends, and proactively managing risks. fruiSCE employs process mining techniques to gain valuable insights into supply chain operations. By analysing event logs and extracting knowledge from existing processes, fruiSCE identifies bottlenecks, inefficiencies, and areas for improvement.

With the comprehensive fruiSCE solution, organizations can unlock new opportunities and achieve unparalleled excellence in supply chain management. By embracing digitization, leveraging supply chain business networks, AI-driven models, process mining, and integrated ERP capabilities, businesses can streamline operations, improve efficiency, and make informed decisions across the supply chain. Experience the power of fruiSCE and gain a competitive edge in today's rapidly evolving business landscape.

Accomplish a successful Supply Chain transformation through fruiSCE

World-class Supply Chain operations...

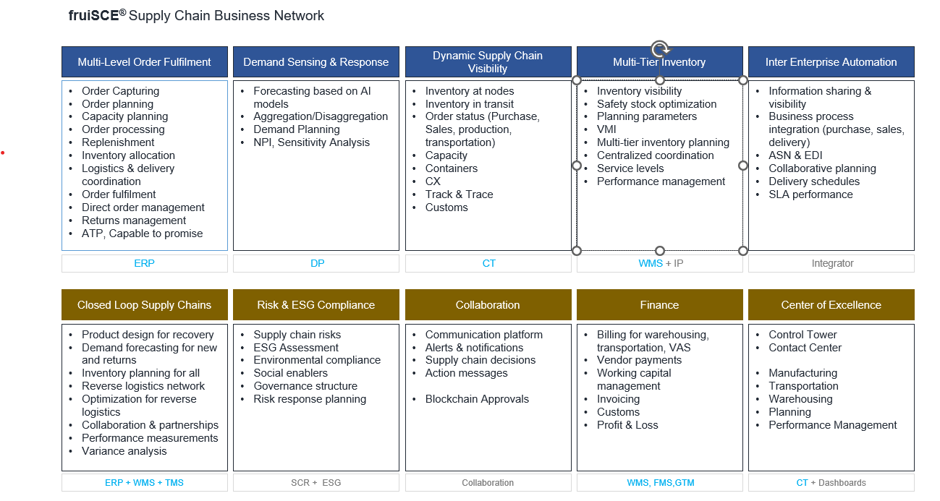

Make your supply chains very competitive, flexible, and responsive through fruiSCE Business Network

fruiSCE Business Network enables interconnected systems and processes that facilitate the flow of goods, services, information, and finances among various supply chain parties. fruiSCE Business Network enable seamless collaboration, visibility, and coordination among suppliers, manufacturers, distributors, retailers, and customers.

fruiSCE enhances the efficiency, responsiveness, and resilience of supply chains by integrating and streamlining operations across different organizations. Empowered by technologies such as AI/ML, cloud computing, big data analytics, the Internet of Things (IoT), process mining, and blockchain to enable real-time data sharing, process automation, and predictive analytics.

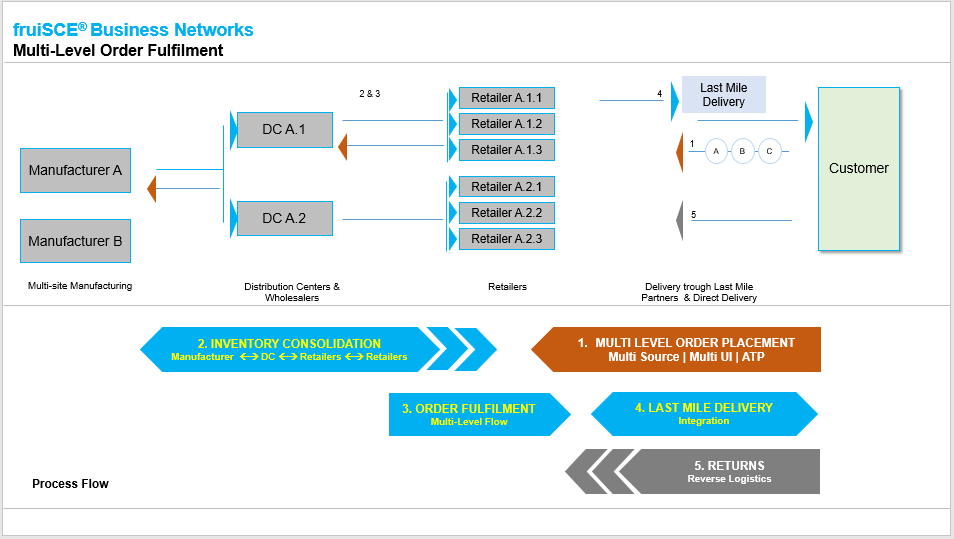

Make your multi-level order fulfilment process simpler, faster, and robust through fruiSCE Business Network

Multi-level order fulfilment in fruiSCE business network involves the process of fulfilling customer orders that involve multiple stages or levels within the supply chain, when your product passes through several entities, such as manufacturers, distributors, and retailers, before reaching the end customer.

Perform all activities such as order placement, order processing, allocation and splitting, intercompany transfers, fulfilment at each level, tracking and visibility, consolidation and shipment, last mile delivery, order completion, and returns management. fruiSCE Business Network empower your supply chain operations to be truly competitive.

Plan demand based on forecasting techniques with real time data and respond to meet or exceed customer expectations

Demand sensing and response in fruiSCE business network refers to the capability to sense and understand changes in customer demand patterns in real time and respond swiftly to meet those demands. It involves the use of forecasting techniques, data analytics, and advanced supply chain algorithms to capture and interpret demand signals from various sources, enabling proactive decision-making and agile response within the supply chain.

Demand sensing and response capabilities empower supply chain organizations to proactively address demand fluctuations, minimize inventory risks, optimize operations, and enhance customer satisfaction.

Demand sensing and response includes real time data integration, generating forecasts based on Artificial Intelligence & Machine Learning models, aggregate and disaggregate, consensus demand planning, rapid response, continuous monitoring to achieve demand and delivery expectations of customers.

Make your supply chains with right inventory all the time through fruiSCE Business Network

Multi-tier inventory management in fruiSCE business networks involves the optimization and coordination of inventory levels across multiple tiers, including suppliers, manufacturers, distributors, and retailers. It focuses on ensuring the right products are available at the right time and in the right quantities by leveraging demand visibility, collaborative planning, safety stock allocation, and centralized inventory visibility.

Multi-tier inventory enables synchronized replenishment, reduces stock outs and excess inventory, enhances supply chain efficiency, and improves customer satisfaction. Through techniques such as vendor-managed inventory and just-in-time practices, multi-tier inventory management drives effective inventory control, cost optimization, and responsiveness within the supply chain network.

View end-to-end supply chain dynamically and take critical decisions faster and better through fruiSCE Business Network

Supply chain visibility in fruiSCE Business Network bring the ability to track and monitor the flow of goods, information, and finances in real time across the entire supply chain. It involves sharing relevant data among stakeholders to achieve transparency, collaboration, and informed decision-making. Supply chain visibility offers end-to-end transparency, allowing stakeholders to track goods, inventory, and order status throughout the supply chain.

Real-time data sharing enables timely decision-making, while collaboration and coordination among partners optimize processes. Supply chain visibility enhances demand and supply planning, risk management, customer satisfaction, and continuous improvement. Overall, it serves as a crucial foundation for achieving transparency, efficiency, and responsiveness in supply chain operations.

Manage returns and reverse logistics with closed loop supply chain execution through fruiSCE Business Network

fruiSCE Business Networks help you to establish a closed-loop supply chain in a sustainable approach that integrates reverse logistics processes into the traditional forward supply chain. It involves managing product returns, recycling, remanufacturing, and reuse to create a circular system where products are not treated as waste but rather as valuable resources.

In a closed-loop supply chain within business networks, stakeholders collaborate to optimize the flow of returned products, implementing efficient reverse logistics processes, and exploring opportunities for remanufacturing or refurbishment. By incorporating closed-loop practices, businesses can minimize waste, reduce environmental impact, improve resource efficiency, and enhance customer satisfaction. Collaboration among network participants is key to successfully integrating reverse logistics into the overall supply chain, ensuring a seamless and sustainable flow of products and materials throughout the network.

Make your supply chains ESG compliant with the help of fruiSCE Business Network

Supply chain ESG compliance involves aligning supply chain practices with environmental, social, and governance principles. Organizations need to assess their supply chain operations, establish standards for suppliers, promote sustainable and responsible practices, and ensure transparency and traceability. By incorporating ESG criteria into supplier contracts, monitoring compliance, and engaging in ongoing collaboration, organizations can drive positive change throughout their supply chain network. This not only helps mitigate environmental and social risks but also enhances brand reputation, attracts socially conscious customers, and aligns with investor expectations for sustainable and responsible business practices.

Supply chain risk management focuses on identifying, assessing, and mitigating risks that can disrupt supply chain operations. It involves proactively evaluating and managing risks such as supplier disruptions, natural disasters, geopolitical issues, and cybersecurity threats. By implementing risk management strategies and contingency plans, organizations can enhance supply chain resilience and minimize the impact of potential disruptions. Robust risk management practices help organizations maintain business continuity, protect customer satisfaction, and safeguard their reputation. In the context of ESG, risk management also encompasses identifying and addressing risks related to environmental impact, labor practices, human rights violations, and ethical sourcing, ensuring compliance with ESG requirements.

Manage finance in supply chain operations to have proper records for accounting and taxation

The finance part in fruiSCE Business Network involves managing the financial aspects related to the movement of goods and services throughout the supply chain. This includes various elements such as billing, invoicing, and payment processing for warehousing costs, transportation costs, and other expenses incurred within the supply chain. The finance processes include billing for warehouse operations, transportation operations, customs, and other supply chain operations can be done through fruiSCE Business Network.

fruiSCE enables you to have supply chain finance aimed at optimizing working capital, improving cash flow, and mitigating financial risks within the supply chain. It includes techniques such as supply chain financing, invoice factoring, dynamic discounting, and vendor financing. These financial solutions provide organizations with options to manage their payables and receivables more efficiently, address cash flow gaps, and strengthen financial relationships with suppliers and customers. fruiSCE provides necessary data requirements and integration options with financial institutions.

Balance Demand & Supply through Integrated Sales & Operations Planning at volume level

Sales and Operations Planning (S&OP) is a strategic business process that aligns demand and supply activities to achieve optimal results. It serves as a bridge between business planning and execution by integrating sales forecasts, demand, and supply chain capabilities. Through S&OP, organizations can effectively manage inventory levels, production capacities, and customer demand fluctuations. By facilitating collaboration among different departments, such as sales, marketing, operations, and finance, S&OP enables informed decision-making and enables businesses to proactively respond to market changes. Successful implementation of S&OP involves defining clear objectives, establishing cross-functional communication channels, and leveraging advanced analytics tools to analyse data and generate actionable insights. By adopting S&OP, businesses can enhance their operational efficiency, optimize resource allocation, improve customer satisfaction, and ultimately drive sustainable growth.

We help organizations to establish Integrated Sales & Operations Process through our products and services and help them to achieve excellence in planning.

Develop realistic demand plans through AI driven forecasting and consensus planning

Demand planning is a crucial aspect of supply chain business operations that involves predicting customer demand for products or services. fruiSCE Demand Planner uses time series techniques and AI models, to generate accurate forecasts and enable businesses to make informed decisions regarding inventory management, production scheduling, and resource allocation.

With the ability to aggregate and disaggregate data, fruiSCE users can analyze demand patterns at different levels of granularity, such as by product, region, or customer segment. This empowers organizations to identify trends, anticipate market fluctuations, and align their supply chain accordingly. By leveraging advanced demand planning tools, businesses can optimize inventory levels, minimize stockouts, reduce costs, and ultimately enhance customer satisfaction through timely and reliable delivery of goods and services.

Explore moreBalance Demand and Supply at mix level through effective Master Scheduling

Master Production Scheduling (MPS) plays a vital role in achieving supply chain excellence by balancing demand and supply at a mix level. It involves developing a detailed plan that synchronizes production activities with customer demand, ensuring optimal utilization of resources and efficient production scheduling. By aligning the manufacturing process with the sales forecast and inventory levels, MPS enables organizations to avoid overproduction or stockouts, minimizing costs associated with inventory holding and shortages.

Through effective MPS with fruiSCE Manufacturing Execution, businesses can optimize production capacities, reduce lead times, and enhance overall operational efficiency. This enables them to respond swiftly to market fluctuations, customer demands, and changing business conditions. By achieving a harmonious balance between demand and supply, organizations can improve customer satisfaction, increase profitability, and ultimately attain supply chain excellence.

Explore more

Maximize capacity utilization and profitability through effective capacity planning

Capacity planning is a critical aspect of overall supply chain planning that involves assessing and managing the resources and capabilities necessary to meet customer demand. It encompasses the strategic allocation of production capacities, labor, equipment, and other resources to ensure that the supply chain operates efficiently and effectively. By carefully analyzing demand patterns, market trends, and production capabilities, capacity planning through fruiSCE, helps organizations determine the optimal level of capacity required to meet customer requirements while avoiding underutilization or overutilization of resources.

This proactive approach allows businesses to make informed decisions about expanding or contracting their production capabilities, improving productivity, and optimizing cost-efficiency. Effective capacity planning enables organizations to align their supply chain operations with market demand, reduce lead times, enhance flexibility, and deliver products and services on time, ultimately driving customer satisfaction and competitive advantage.

Plan Material to be available at the right time in right quantities and eliminate stockouts through better MRP

Materials Requirements Planning (MRP) is a crucial process in supply chain management that involves determining the optimal inventory levels and timing for raw materials, components, and finished goods. By analyzing production schedules, sales forecasts, and current inventory levels, MRP generates a comprehensive plan for material procurement, ensuring that the right materials are available at the right time to support production and meet customer demand.

Through fruiSCE we generate effective MRP and organizations can minimize stockouts, reduce excess inventory, and optimize production efficiency. It enables businesses to streamline their supply chain operations, improve order fulfilment rates, and enhance customer satisfaction. By accurately assessing material requirements, monitoring inventory levels, and aligning production schedules, MRP plays a vital role in maintaining a lean and agile supply chain, enabling businesses to operate efficiently, minimize costs, and respond quickly to changing market dynamics.

Explore more

Improve asset utilization, maximize production capacity, and deliver to customer all as required

Production scheduling is the key priority for production managers to focus on efficiently allocating resources and sequencing production orders to meet customer demands. Its primary objective is to ensure that machines and labor are effectively utilized to deliver products to customers on time and in full. By analyzing factors such as production capacities, lead times, and order priorities, production scheduling aims to optimize production sequences, minimize idle time, and maximize throughput.

Through effective scheduling, organizations can avoid bottlenecks, balance workloads, and maintain a smooth and efficient production flow. fruiSCE help production managers to synchronize production activities with customer demands and enables businesses to meet delivery deadlines, enhance customer satisfaction, and maintain a competitive edge in the market.

Explore moreGenerate Transportation Plans to achieve supply chain excellence

Transportation planning is a very important element of supply chain management that involves strategically organizing and optimizing the movement of goods from one location to another. It encompasses the planning, routing, and scheduling of transportation activities to ensure efficient and cost-effective delivery of products. Transportation planning takes into account various factors such as shipment volumes, transportation modes, distance, delivery time requirements, and cost considerations. By analyzing these factors, organizations can design transportation networks that minimize transit times, reduce transportation costs, and maximize overall supply chain efficiency.

Effective transportation planning enables businesses to optimize their logistics operations, improve inventory management, and enhance customer service by ensuring timely and reliable delivery. It also helps organizations identify opportunities for collaboration, such as consolidation of shipments or utilizing intermodal transportation, to further streamline their transportation processes and reduce environmental impact. Ultimately, transportation planning plays a vital role in achieving operational excellence, driving customer satisfaction, and gaining a competitive advantage in the marketplace.

Explore more

Prepare optimal purchasing schedules to align suppliers, reduce costs, and eliminate stockouts

Purchase scheduling is an integral planning process to optimize overall supply chain performance. By strategically planning and coordinating procurement activities, organizations can achieve efficient inventory management, minimize stockouts, and reduce costs. Purchase schedules take into account factors such as production requirements, lead times, supplier capabilities, and market demand. By aligning these factors, organizations can optimize the timing and quantity of purchases, ensuring that materials and components are available when needed while avoiding excess inventory.

Effective purchase scheduling enables businesses to streamline their supply chain, enhance supplier relationships, and improve cash flow by optimizing payment terms and negotiating favourable contracts. By optimizing purchase schedules, organizations can achieve greater visibility and control over their supply chain, improve operational efficiency, and ultimately deliver value to customers through timely and cost-effective production and delivery of goods and services.

Explore moreAchieve excellence in order-to-cash process to meet or exceed customer expectations

Order management involves end-to-end process of capturing, processing, and managing customer orders efficiently and accurately. Effective order management ensures that customer orders are entered correctly, promised delivery dates are realistic, and orders are fulfilled and delivered on time. By implementing robust order management practices through fruiSCE, organizations can achieve supply chain excellence by optimizing inventory levels, improving order fulfilment cycles, minimizing errors and delays, enhancing customer satisfaction, and ultimately increasing profitability.

With streamlined order management processes, organizations can achieve better visibility into order status, improve order accuracy, and effectively allocate resources, enabling them to respond swiftly to changing customer demands and market dynamics.

Explore more

Reduce overall costs by efficient procure-to-pay process and eliminate stock outs

Procure-to-pay is a key process within the supply chain that involves the entire cycle from procurement to payment for goods and services. It encompasses activities such as supplier selection, purchasing, receiving, invoicing, and payment processing. Procure-to-pay plays a crucial role in achieving supply chain efficiency and responsiveness for organizations. By implementing an effective P2P process through fruiSCE, organizations can streamline their procurement operations, ensure timely availability of materials and services, reduce costs, and maintain strong supplier relationships.

Through automated procurement systems and digital workflows, Procure-to-pay enables organizations to improve purchasing cycle times, enhance accuracy in procurement transactions, optimize inventory levels, and negotiate favourable terms with suppliers. By achieving supply chain efficiency and responsiveness through an effective Procure-to-pay process, organizations can gain a competitive edge by minimizing procurement lead times, mitigating supply disruptions, and effectively managing working capital.

Explore moreAchieve excellence in manufacturing process through fruiSCE

The end-to-end manufacturing process encompasses all the stages involved in transforming raw materials into finished products, including product design, planning, sourcing, production, quality control, and distribution. By optimizing the end-to-end manufacturing process through fruiSCE, organizations can achieve several benefits. Firstly, it allows for improved production planning and scheduling, enabling better synchronization of manufacturing activities with customer demand. Secondly, it enhances operational efficiency by minimizing waste, reducing production lead times, and increasing productivity through streamlined processes and automation. Thirdly, it enables effective inventory management by ensuring the right levels of raw materials, work-in-progress, and finished goods.

Furthermore, it facilitates better collaboration and coordination with suppliers and customers, enabling seamless information flow and timely response to market changes. By focusing on excellence in the end-to-end manufacturing process, organizations can achieve greater supply chain agility, cost savings, higher customer satisfaction, and a competitive advantage in the marketplace.

Explore more

Empower your supply chains with robust warehousing processes

Warehouse management is an integral part of supply chain execution process that help organizations to achieve customer service levels. It involves the systematic planning, organizing, and controlling of all activities within a warehouse, including receiving, putaway, picking, packing, and shipping. fruiSCE enables optimized space utilization, ensuring that the layout and storage systems are designed to maximize storage capacity and minimize unnecessary movement. fruiSCE facilitates accurate inventory management through real-time tracking and monitoring of stock levels, reducing the risk of stockouts or excess inventory. fruiSCE improves order fulfilment by establishing efficient picking strategies, optimizing pick routes, and implementing quality control measures.

Aligned warehouse management processes through fruiSCE allow for effective labor management, ensuring that staffing levels, training, and performance management are properly addressed. By aligning warehouse management processes, organizations can achieve enhanced operational efficiency, improved customer service, reduced costs, and better overall supply chain performance.

Explore moreEnsure customer service levels through integrated transportation process

fruiSCE Transportation and fleet management play an integral role in helping supply chain organizations achieve excellence in their operations. Efficient transportation and fleet management through fruiSCE processes ensure the timely and cost-effective movement of goods from suppliers to customers. By optimizing transportation and fleet operations, organizations can achieve several benefits. Firstly, it enables improved delivery reliability and reduced lead times, leading to enhanced customer satisfaction. Secondly, it helps in minimizing transportation costs by optimizing routes, consolidating shipments, and selecting the most efficient transportation modes. Thirdly, it facilitates effective inventory management by ensuring timely replenishment and reducing stockouts.

Furthermore, transportation and fleet management provide visibility into the movement of goods, allowing organizations to proactively address any disruptions or delays in the supply chain. By leveraging fruiSCE transportation management and fleet tracking systems, organizations can achieve real-time visibility, improve route planning, enhance communication with carriers, and optimize resource utilization. Ultimately, effective transportation and fleet management contribute to overall supply chain excellence by ensuring smooth logistics operations, reducing costs, enhancing customer service, and maximizing operational efficiency.

Explore more

Align global trade management processes to achieve supply chain efficiency

Global Trade Management (GTM) help organizations to achieve excellence in overall supply chain operations. fruiSCE GTM encompasses the processes that enable organizations to effectively manage and optimize their global trade activities. It involves all activities of trade compliance, customs documentation, duty and tariff management, trade finance, and global logistics coordination. By implementing robust GTM practices, organizations can achieve several benefits.

Firstly, it ensures compliance with complex international trade regulations, mitigating the risk of penalties, delays, and reputational damage. Secondly, it facilitates accurate and timely documentation, reducing the chances of customs-related issues and ensuring smooth cross-border movement of goods. Thirdly, GTM enables organizations to optimize their supply chain by identifying cost-saving opportunities, leveraging preferential trade agreements, and managing duties and tariffs effectively. Furthermore, it enhances visibility and control over global trade processes, enabling proactive decisions.

Explore moreOptimize your supply chain operations through models built on operation research algorithms

Optimization algorithms can be powerful tools for addressing various supply chain problems. While heuristics often provide efficient and practical solutions, optimization algorithms can offer optimal or near-optimal solutions. fruiSCE include algorithms embedded in supply chain excellence solutions which are custom built for the client requirements.

Explore more

Identify the bottlenecks and inefficiencies through process mining across supply chain operations

Process mining is a valuable technique in the context of supply chain management, enabling organizations to gain insights into their operational processes and identify opportunities for improvement. By analyzing event logs and transactional data generated during the execution of supply chain activities, process mining techniques can uncover the actual flow of goods, information, and resources across the supply chain network.

This analysis helps identify process inefficiencies, bottlenecks, and deviations from the intended process design. Through process discovery, conformance checking, and enhancement, process mining enables supply chain managers to optimize process performance, streamline operations, reduce lead times, and enhance overall supply chain efficiency and responsiveness. It provides a data-driven approach to process optimization, allowing organizations to make informed decisions and drive continuous improvement in their supply chain operations.

Custom built OR models can help you to optimize your supply chains

Facility Location Problem: Determining the optimal locations for warehouses, distribution centers, or manufacturing facilities to minimize costs or maximize service levels.

Inventory Optimization: Finding the right balance between inventory levels and customer service levels to minimize costs while meeting demand.

Vehicle Routing Problem: Optimizing the routing and scheduling of vehicles to deliver goods to customers or replenish inventory at multiple locations while minimizing transportation costs or travel distances.

Production Planning and Scheduling: Optimizing the allocation of resources (such as machines, labor, and materials) and scheduling of production activities to meet demand while minimizing costs or maximizing efficiency.

Network Design and Optimization: Determining the optimal structure and configuration of the supply chain network, including the number and location of facilities, transportation routes, and flows between different nodes, to minimize costs or maximize responsiveness.

Supply Chain Network Optimization: Optimizing the end-to-end supply chain network, considering various factors such as procurement, production, transportation, inventory, and demand, to minimize costs, lead times, or environmental impacts.

Demand Forecasting and Planning: Utilizing optimization algorithms to improve the accuracy of demand forecasting and optimize production or procurement plans based on the forecasted demand.

Multi-Echelon Inventory Optimization: Optimizing inventory levels and replenishment policies across multiple echelons of the supply chain, considering demand uncertainty, lead times, and service level targets.

Load Balancing and Capacity Planning: Optimizing the allocation of workload or capacity across different resources or facilities to ensure efficient utilization and minimize bottlenecks.

Supplier Selection and Sourcing Optimization: Selecting the optimal suppliers and determining the optimal allocation of sourcing volume to different suppliers considering factors such as costs, quality, lead times, and risks.

Achieve successful supply chain digital transformations through fruiSCE solutions

The critical components of supply chain digital transformation include automating key supply chain planning and execution processes, by utilising data analytics, inter-enterprise integrations, and supply chain collaboration.

Leveraging advanced technologies such as AI, ML, IoT, and cloud computing enables automation, real-time data collection, and analysis, facilitating better decision-making and operational efficiency. Data analytics plays a crucial role in extracting meaningful insights from large volumes of data, driving optimization and predictive capabilities.

Integration of systems and processes, both internally and externally with partners and suppliers, enables seamless information flow and end-to-end visibility. Collaboration across the supply chain ecosystem fosters coordination, agility, and innovation, leading to improved responsiveness and customer satisfaction.

Supply chain digital transformation is a process to execute strategy to build competitive supply chains

To achieve supply chain digital transformation, organizations need to take a systematic approach. This involves conducting a comprehensive assessment of the existing supply chain processes, technology landscape, and data availability. Based on this assessment, a clear vision and strategy should be defined, outlining the desired outcomes and key milestones. Organizations should invest in technology infrastructure and platforms that support the digital transformation goals, ensuring scalability, flexibility, and security.

Implementing robust data governance practices and ensuring data quality and integrity are essential for accurate insights and decision-making. Additionally, organizations need to focus on change management and employee upskilling, fostering a digital culture and ensuring the adoption and utilization of new technologies and processes. Continuous monitoring, evaluation, and refinement of the digital transformation initiatives are necessary to stay aligned with evolving business needs and technological advancements.

Achieve visibility and control through custom build Control Tower for your industry

fruiSCE supply chain control tower serves as a centralized hub that offers end-to-end visibility and real-time monitoring of the supply chain. By aggregating data from multiple systems and processes, it provides comprehensive insights into inventory levels, demand patterns, production status, transportation movements, and supplier performance. This visibility enables organizations to identify inefficiencies, delays, and disruptions, allowing them to take proactive measures and make data-driven decisions.

The control tower also promotes collaboration among stakeholders by facilitating real-time communication, coordinated planning, and collaborative problem-solving. Leveraging advanced analytics and predictive models, it empowers organizations to anticipate future demand, optimize inventory, and mitigate risks. fruiSCE control tower enables performance monitoring through real-time metrics and KPIs, driving continuous improvement and operational optimization. By enhancing agility and resilience, the control tower enables organizations to respond quickly to market changes, disruptions, and customer demands.

Explore more

Execute Strategies Consistently through fruiStrategy

Supply chain excellence is undeniably the most crucial aspect of strategy execution and balanced scorecard is extremely useful to align supply chains to the organization. By integrating the supply chain function into the scorecard's key performance indicators (KPIs), organizations can ensure that their strategic objectives are effectively translated into tangible results.

Achieving supply chain excellence enables seamless coordination and synchronization of activities across the entire value chain, encompassing suppliers, manufacturing, distribution, and customer service. This alignment not only enhances operational efficiency, cost optimization, and quality control but also facilitates enhanced customer satisfaction, market responsiveness, and ultimately, sustainable competitive advantage. Thus, supply chain excellence serves as the vital link that bridges strategy formulation with successful strategy execution, fostering organizational success and long-term growth.

Explore moreMeasure Supply Chain Performance and ensure planning and operations deliver results

Supply chain performance management plays a pivotal role in optimizing the efficiency and effectiveness of end-to-end supply chains. By systematically measuring, monitoring, and improving key performance indicators (KPIs) across the entire supply chain network, organizations can enhance their operational performance and achieve strategic objectives. This comprehensive approach encompasses various aspects, including supplier performance, production and inventory management, logistics and transportation, and customer service.

By closely monitoring these metrics and benchmarking them against industry standards and best practices, companies can identify areas for improvement, drive continuous process enhancements, and make informed decisions to enhance overall supply chain performance. With effective supply chain performance management, organizations can gain better visibility, control, and agility in their end-to-end supply chains, leading to improved customer satisfaction, cost reduction, revenue growth, and competitive advantage in today's dynamic business landscape.

Upcoming Event

Global Chain Supply Excellence Summit Edition - 7

Date:28thFebruary 2026

Accomplish a successful Supply Chain transformation through fruiSCE, World-class Supply Chain operations.

- Data Labs India Solutions pvt ltd.

- Plot No. 1-11-301/3, 3rd Floor AU Reddy Towers, Gagan Vihar Colony Begumpet – 500016, Hyderabad, TS, India

- Phone: +91 7799798333

- E-Mail: [email protected]

Product

- Business Networks

- Enterprise Resource Planning

- Manufacturing Execution

- Warehouse Management

- Control Tower

- Fleet Management

- Transport Management

- Demand Planning

- Global Trade Management

- Supplier Connect Manufacturing

- Manufacturing Execution Syetem

- Job Shop Manufacturing

- Discrete Assembly Manufacturing

- Process & Batch Manufacturing

- Integrations Warehousing

- Warehouse Management System

- WMS 3PL 4PL

- Yard Management System

- WMS Manufacturing Units

- Distribution Centers & Cold Storage Logistics

- Fleet Management System (FMS)

- Global Trade Management

- TMS for 3PL and 4PL

- GPS & Integrations Planning & Optimization

- Demand Planning

- Supply Chain Optimization ERP & Business Network

- Enterprise Resource Planning

- Business Networks

- Control Tower